Many of mould buyers they have headache of mould suppliers’ delivery time. Most mould manufacturers are always delaying the delivery time. As we all know an old saying that Time is Money! Now comes the question, how to shorten the mould delivery time to make buyers’ profit maximum?

Firstly let’s talk about the mould design. In some factories the young designers do not have much experience, sometimes they designed mould structure is unreasonable. And the problem been found till the moulds testing, then the mould maker need to spend a lot of time and effort to rectify the mould. So, a good mould design is the fundamental and first step to ensure deliver on time.

Secondly, correct and suitable tooling should be taken. Many mould makers in order to save tooling cost, they do not use high precision tooling equipments and the work piece is not meet precision requirements, then mould maker need to re-tooling or change the part. It’s waste of time!

Aero Mould is a mould factory that respects our customers’ valuable time. We give our mould buyers best mould design. And we use standard mould base to ensure the mould quality and greatly shortened our delivery time.

China plastic chair mould supplier AERO MOULD is a professional plastic moulds factory in China, we make nearly 28 sets various types chair moulds each year. We have made stadium seat mould, leisure chair mold, beach table&chair mould, ghost chair molds, etc.

In the year of 2015, rattan design becomes very popular, we have made 4 sets rattan chair mould successfully.

Generally, we use P20 steel for chair moulds and sometimes 718H is for high quality chair moulds. Guaranteed mould life 3 million shots runs fully automatically. Mould delivery time 45 days after deposit and mould design approved by customer.

If you are interested to buy a chair mould, pls feel free to email to

chinamould@aeromould.com, our rich experience ensures you the best quality. We look forward to cooperate with customers all over the world!

AERO MOULD is a experienced plastic injection mold manufacturer in China. We are specialized in making thin wall mold, double color mold, house hold product mold, pipe fitting mould, preform and cap mould, etc.

As now we are expanding, we are looking for agency all around the world. The agency could be a single person or a company. The agency should have good knowledge of plastic molds and have strong selling ability.

If anyone have good knowledge, selling ability and feel interested to be a agency, pls feel free to contact mail us via chinamould@aeromould.com

Seasoning bottle or condiment dispenser may called, is very commonly used in kitchen. Day by day people are attracting to the fancy daily products, we help our client to develop, design and building fancy products mould.

This

seasoning bottle series has 250ml, 440ml, 500ml, 650ml, 800ml, 890ml available. The bottle was made of PP and cap made of PE material.

We applied special spout design for oil bottle so to avoid leakage, and a small cap for the spout will be dustproof. Compared to aluminum seasoning bottle, you can easily tell what spices was loaded in each bottle and you can easily see how much was left in the bottle.

If you are interested to develop such fancy daily products mould, pls feel free to send us enquiry. If you have new ideas for new products, pls come to us, we will make design according to your requirements. We are always ready to serve our customer with our rich experience.

Email

chinamould@aeromould.com Mob & whatsapp +86 13666469798

Most housewives are annoyed with all the clutters make the kitchen or house in a mess, and they are always complain that the storage space is not enough, expecially they have baby. Now it's a good chance for you to make a new business and solve their problem!

We have once made a storage rack mould. This storage rack width is only 130mm, so you can put it in the gap between your furniture. It can be put in the kitchen, bathroom etc. This rack is equiped with small wheel, when you need to take something, it's very convenience. Additionally, this storage rack is removable, you can make it multi-layer as you like.

This kind of storage rack is very popular in the housewives. If you are interested to buy a mould for storage, pls feel free to contact us. Pls feel free to send email to

chinamould@aeromould.com skype ritapanpyl

Today, more and more housewives are using plastic containers for food or fruit storage. This lead to many more people engaged in food package products producing.

Thin wall food containers and thin wall buckets are becoming popular used in daily life.

For many new beginners, they do not have technical skills of injection molding. So here we will introduce some tips to judge a good

thin wall mould.

1. Mould design inspection. There’re many designers they do not have experience of making a mould, so they cannot take everything into consideration. Few days ago, a Turkey customer came to me and told me the mould they presently using has too much cooling time. When our engineer studied their mould drawing, we found that the cooling line did not cool the products. Then our engineer drew a rough drawing to suggest them with new design to shorten the cooling time. This story is telling that a good design really plays a very important role, a good mould design really can reduce the cycle time so to save production cost.

2. Mould steel selection. Thin wall moulds usually working under big pressure and high speed, so the steel should use vacuum hardening steel with higher HRC. Aero Mould generally us S136 stainless steel for core and cavity, with HRC 48-52.

3. Hot runner selection. Thin wall mould requires hot runner to make raw material melt and flow faster, so to reduce cycle time. If the hot runner is bad quality, it’s really a very complicated problem during production.

4. Injection molding machine condition. A high speed IMM shall use for fast production. And make sure the mould is cooperating perfect with the machine.

Post by MS. Rita email chinamould@aeromould.com Mob. +86 13666469798

Double color mold currently growing popularity on the market is because of this process can make the product look more beautiful and easy to change the color without paint.

Here are some tips for design a double color mould

1.When design the mould must check the movable&fixed half mould rotated by 180 ° Should be in consistent. This demanding high requirements of mould frame positioning processing

2.The total thickness of the front plate and A plate should not less than 170mm.

3. When design the mould, 1st color product can be designed slightly larger, so to make it match more tight with 2nd color core, so it will not come out flashes.

4. To avoid melted material will flood the first color molded prduct while molding the 2nd color.

5. Make cooling line layout evenly on core and cavity part

6. To avoid slider and angle lift injury the product when they return

email chinamould@aeromould.com skype ritapanpyl

plastic mold manufacturer AERO MOULD is a experienced moulds supplier in China.Our main products are thin wall mold,double color mould,houseware moulds,PET preform moulds,cap mold,industrial moulds,etc.

Our main business is

1- Double color mold series: double color cup, bowl mold

2- thin wall mold series: food container mould, ice cream mold, flower pot moulds

3- IML mold series: paint bucket mold with IML, food container mold

4- transportation series: plastic crate mold, pallet mould, beer crate moulds

5- package mold series: PET preform mold, PET jar molds, cap and closure mould

6- pipe fitting mold series: PVC pipe fitting mold, PPR fitting mould

7- houseeware and home appliance mold: refrigerator mold, washing machine mould, air conditioner moulds

We have experienced mold design and mold making team to ensure the quality. We will shorten the delivery time and molding cycle time, make your proudcts into market in advance!

AERO MOULD is a experienced

PET preform mould making factory in China. We are good at making 4 cavity to 72 cavity PET preform moulds. PET containers are widely used for milk, juice, water and other application, as a top preform mold maker in China, we are always available to offer our customer turnkey solution for their PET preform molding.

Optimal cooling design greatly shortened the cycle time.

Stainless steel ensures high transparency of preforms, and make mould life longer.

High precision tooling core and cavities make each core and cavity interchangeable with each other.

Extra core and cavities were made for customers as spare parts.

If you are looking for

PET preform moulds, a good contact is Ms. Rita from AERO MOULD. In AERO MOULD, mould quality is promised.

Post by Rita email

chinamould@aeromould.com mob 86 13666469798

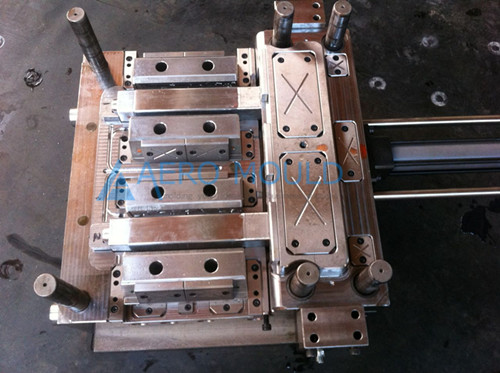

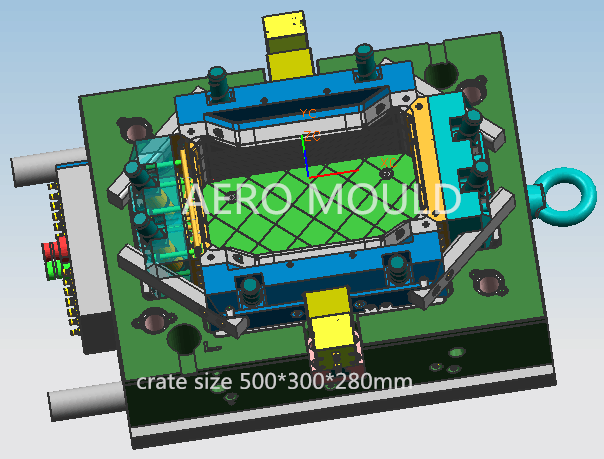

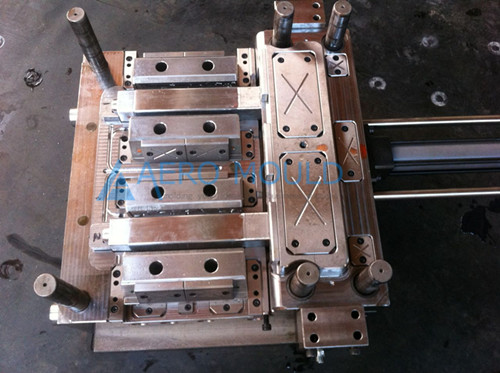

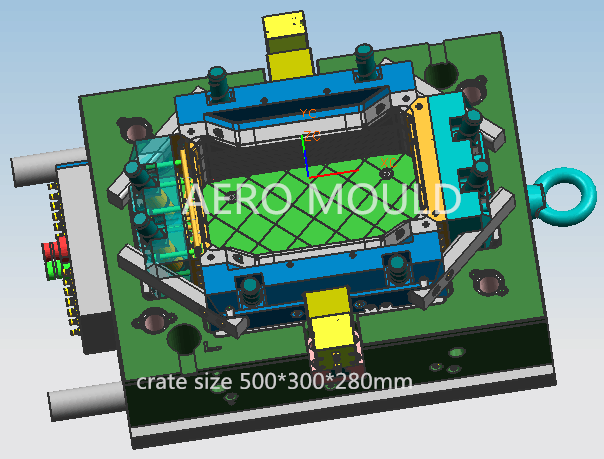

Crate mould is the core business of AERO MOULD for many years. We make vegetable crate mold, milk crate mold, beer crate moulds, bread crate mould, etc.

Vegetable crate size 500*300*280mm

Material PP

Crate weight 1500gm

Crate mold size 1100*650*830mm

Runner system 4 drops hot runner

Mold steel P20

Cycle time 50S

Delivery time 45 days

If you are looking for a good crate mold manufacturer, AERO MOULD will be your best choice! We have rich experience in making plastic crate molds, we ensure you good quality and fast delivery time.

post by Rita email

chinamould@aeromould.com QQ 3038406347 skype ritapanpyl

Today the double color fruit bowl mold been tested successfully. We did it a great job, because this is the first trial of this

double color mould. Here are the double color mold specifications:

Mould name: double color fruit bowl mould

Mould size: 450*300*400mm

Mould cavity: single cavity

Mould steel: H13 with HRC45-48 after heating treatment

Runner: hot runner pin point runner

Product size: 200*100*60mm

Wall thickness: 7mm

Cycle time: 30 seconds

Delivery time: 40 days

If you are looking for double color moulds, AERO MOULD is a professional and experienced

double color moulds making factory in China, we are not only offer you a double color mould, but also a turnkey solution for you double injection molding! We promise molding your ideas into business success!

Post by Rita email

chinamould@aeromould.com skype ritapanpyl

Thin wall mold manufacturer AERO MOULD specialized in making thin wall food container mould, IML container mold, thin wall flower pot mould, etc.

As the thin wall mould usually working under high speed and high pressure, and the mould requires cooling water, we consider stainless steel S136 and DIN.1.2316 as the core and cavity steel. P20 was used for the mould base to ensure the mold strength.

For the easy damage part we make according to international standard, so when the parts damaged, customer can change the part at their local market easily.

Thin wall molds require good polishing to ensure perfect surface finishing. We ensure mirror polishing for every thin wall mold.

If you are looking for plastic molds, pls feel free to contact us!

Post by Rita email

chinamould@aeromould.com QQ 3038406347